Views: Author: SCBN TOOLS Publish Time: 2026-01-09 Origin: Site

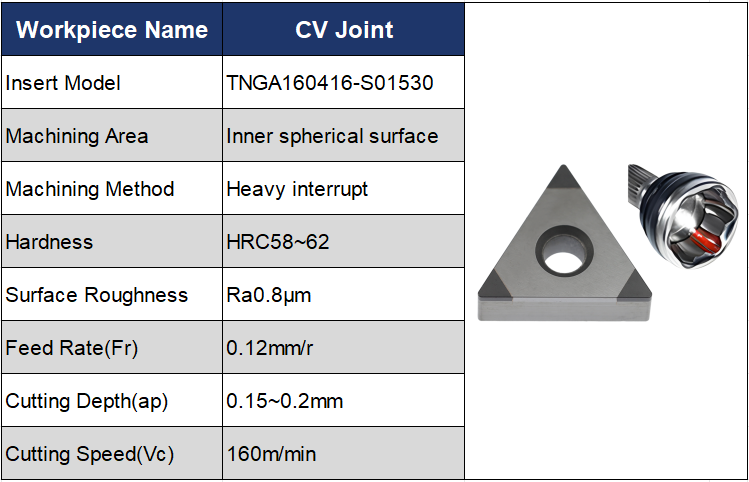

For the machining of the outer CV joint inner spherical surface, precision is paramount. High-hardness materials such as hardened steel (HRC58-62) are widely used for outer CV joints, posing strict requirements on machining tools and processes. Tools like SCBN TOOLS TNGA160416 PCBN inserts are preferred for their excellent wear resistance, impact resistance, and thermal stability, ensuring high-precision machining of the inner spherical surface with a tolerance of ±0.003mm and surface roughness Ra≤0.8μm.

In practical applications, processing efficiency is increased by over 40%, processing life is extended by over 25%, and the product pass rate reaches 99.5%, balancing precision, efficiency, and cost, and meeting the mass production requirements of the automotive manufacturing industry.

Address : No. 11, Ruida Road, high tech Zone, Zhengzhou, Henan, CHINA

Tel : +86-13271567751

Fax : +86-0371-56705820

E-mail :scbntools@gmail.com

WeChat: scbntools annachina6