Views: Author: SCBN TOOLS Publish Time: 2026-01-06 Origin: Site

As the automotive manufacturing industry continuously raises its demands for efficiency, precision, and cost control in parts processing, the machining of grooves i n cast iron brake discs, a critical safety component, faces rigorous challenges. SCBN TOOLS' CBN grooving inserts, leveraging the properties of superhard materials and precise structural design, have achieved a technological breakthrough in the grooving of brake discs made from materials such as gray cast iron (e.g., FC250 and FC300 standards).

n cast iron brake discs, a critical safety component, faces rigorous challenges. SCBN TOOLS' CBN grooving inserts, leveraging the properties of superhard materials and precise structural design, have achieved a technological breakthrough in the grooving of brake discs made from materials such as gray cast iron (e.g., FC250 and FC300 standards).

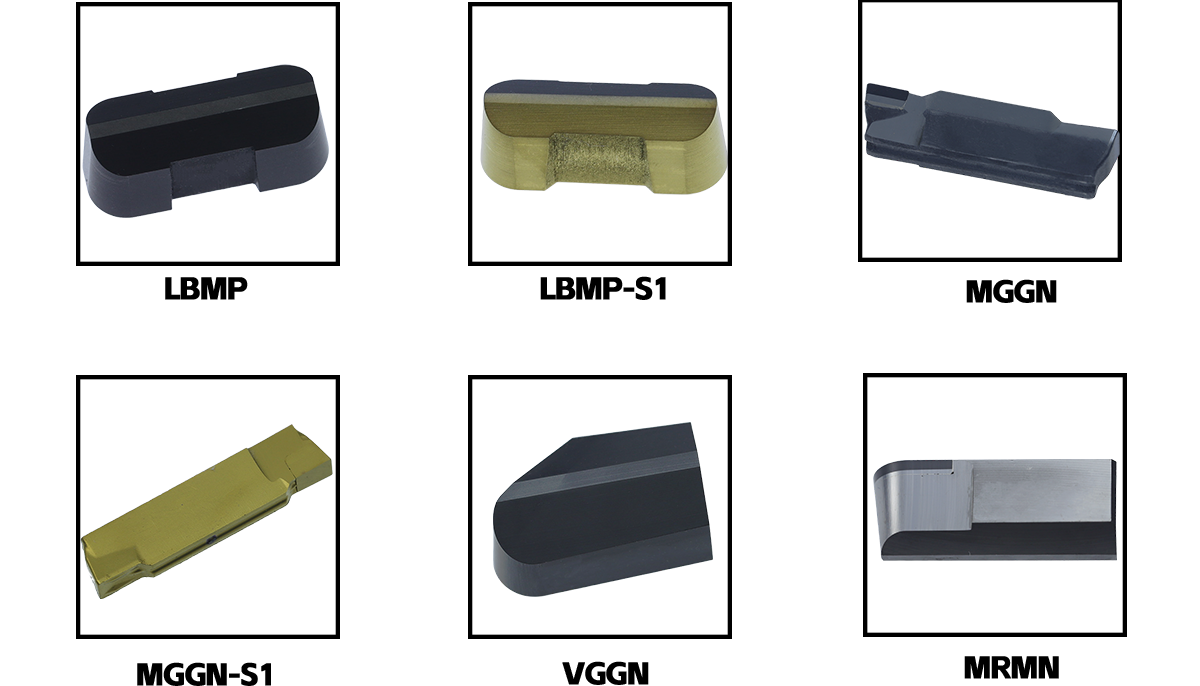

I. Core Types of SCBN TOOLS CBN Grooving Inserts

1. Solid CBN Grooving Inserts: Main models include GBMP, LPGN, VGGN, and LBMP series, suitable for heavy-duty, large-allowance rough grooving of cast iron brake discs.

2. Flat-Head CBN Grooving Inserts: The core model is the MGGN series, offering both cost-effectiveness and durability, primarily used for semi-finishing and finishing grooving of cast iron brake discs.

3. Round-Head CBN Grooving Inserts: The representative model is the MRMN series. This series of tools is suitable for high-toughness cast iron materials such as ductile iron, providing stable and vibration-free cutting, and is specifically designed for machining curved grooves and rounded transition grooves in cast iron brake discs.

4. Coated CBN Grooving Inserts: Coated CBN grooving inserts reduce friction and heat loss during the cutting process, minimizing adhesive wear between the tool and the cast iron workpiece, and are suitable for high-speed precision machining applications.

II. Core Advantages of SCBN TOOLS CBN Grooving Inserts for Machining Cast Iron Brake Discs

Compared to traditional carbide and ceramic grooving inserts, SCBN TOOLS CBN grooving inserts comprehensively address the challenges of machining cast iron brake discs with their diverse designs and material advantages:

1. Ultra-long service life, reducing tool replacement costs

2. High-speed cutting capability, improving processing efficiency

3. Excellent machining accuracy, ensuring surface quality

4. Strong adaptability to various working conditions and wide range of applications

III. Practical Application Cases

Case Study: Mass Production of FC250 Gray Cast Iron Brake Discs by a Large Automotive Parts Manufacturer

1. Machining Requirements

The workpiece material is FC250 gray cast iron (HB190-210). A thermal compensation groove with a width of 6mm and a depth of 5mm needs to be machined. The requirements include a mass production efficiency of ≥500 pieces/day, a groove surface roughness of ≤Ra1.6μm, and a tool life of ≥200 pieces/edge.

2. Solution

The SCBN TOOLS GBMP0600 integral grooving tool with SBN850 high-performance grade was selected. The cutting parameters were set as follows: cutting speed vc = 534 m/min, feed rate fr = 0.26 mm/r, and cutting depth ap = 0.4 mm.

3. Application Results

Machining efficiency: The average daily output increased to 620 pieces, a 35% improvement compared to the original carbide tools;

Tool life: The tool life was 8 times longer than that of the original carbide tools;

Machining quality: The groove surface roughness was consistently maintained at Ra1.2-1.5μm, the dimensional tolerance was controlled within ±0.02mm, and the product pass rate increased from 96.8% to 99.7%.

Address : No. 11, Ruida Road, high tech Zone, Zhengzhou, Henan, CHINA

Tel : +86-13271567751

Fax : +86-0371-56705820

E-mail :scbntools@gmail.com

WeChat: scbntools annachina6