CBN grooving inserts are specialized grooving tools made from CBN (a superhard material second only to diamond in hardness), specifically designed for machining high-hardness materials. They maintain stability at temperatures exceeding 1200°C, achieving cutting efficiency 3-5 times of conventional carbide cutters. They maintain a slot width tolerance of ±0.01mm and a slot surface roughness of Ra0.8-1.6μm. CBN grooving inserts are primarily used for machining hardened steel and cast iron and other parts. Common types of CBN slotting cutters are as follows:

Solid CBN grooving inserts, please click on the link below, CBN grooving inserts can be used to replace ceramic grooving inserts.

In the past, ceramic grooving inserts were often used for machining brake discs. However, due to their inherent limitations, SCBN with a customer-focused approach, has continuously developed and introduced high-performance CBN grooving inserts to replace ceramic inserts. In addition, the use of SCBN grooving inserts for machining brake discs has been successfully demonstrated in the global.

CBN grooving inserts: Because their high hardness, high-temperature resistance, chemical inertness, and impact resistance, CBN grooving inserts are the undisputed top choice for machining cast iron and hardened steel. Their long lifespan and stability significantly reduce unit costs, making them particularly suitable for high-volume production. Other materials (such as carbide and ceramics) are unable to replace the advantages of CBN due to rapid wear or material limitation. CBN grooving inserts can be used for both roughing and semi-finishing.

CBN grooving inserts replace ceramic grooving inserts can reduce costs by 30% and increase tool life by 55%.

Ceramic Grooving Inserts

CBN Grooving Inserts(Brand: SCBN)

Tipped CBN Grooving Inserts:

MGMN, we can provide up to MGMN900.

Model

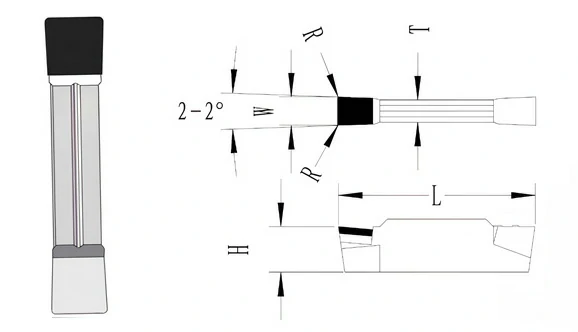

| Width/W | Thickness/T | Length/L | Height/H | Radius/R | Drawing |

| MGMN150 | 1.5 | 1.2 | 16 | 3.5 | 0.2 |

|

| MGMN200 | 2.0 | 1.6 | 16 | 3.5 | 0.2 |

| MGMN250 | 2.5 | 2.0 | 18.3 | 3.65 | 0.2 |

| MGMN300 | 3.0 | 2.35 | 21 | 4.8 | 0.2 |

| MGMN400 | 4.0 | 3.3 | 21 | 4.8 | 0.2 |

| MGMN500 | 5.0 | 4.1 | 26 | 5.8 | 0.2 |

MRMN, we can provide up to MRMN900. The minimum radius can be 0.75.

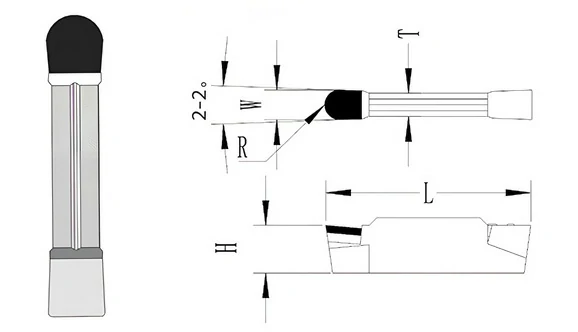

| Model | Width/W | Thickness/T | Length/L | Height/H | Radius/R | Drawing |

| MRMN150 | 1.5 | 1.2 | 16 | 3.5 | 0.75 |

|

| MRMN200 | 2.0 | 1.6 | 16 | 3.5 | 1 |

| MRMN250 | 2.5 | 2.0 | 18.3 | 3.65 | 1.25 |

| MRMN300 | 3.0 | 2.35 | 21 | 4.8 | 1.5 |

| MRMN400 | 4.0 | 3.3 | 21 | 4.8 | 2 |

| MRMN500 | 5.0 | 4.1 | 26 | 5.8 | 2.5 |

For non-standard grooving inserts, they can be customized according to the drawings.

Common CBN grooving inserts for replacing ceramic grooving isnerts

NBMN12F100, NBMN12F120, NBMN15F150, NBMN19F190, NBMN24F250

GBMP 12 A 0400, GBMP 12 A 0500, GBMP 12 A 0600, GBMP 12 A 0700, GBMP 12 A 0800

LBMP 12 A 0400, LBMP 12 A 0500, LBMP 12 A 0600, LBMP 12 A 0700, LBMP 12 A 0800

LBMP 12 A 040, LBMP 12 A 050, LBMP 15 E 060, LBMP 15 E 070, LBMP 15 E 080, LBMP 15 E 100

GWF 04, GWF05, GWF 06, GWF07, GWF 08, GWF 10

GWG 04, GWG 05, GWG06, GWG 07, GWG 08, GWG10

Other CBN grooving inserts we can offer: CTP, CTPA, TDT

The advantages of CBN grooving inserts:

1. Longer tool life—reducing tool change time and costs.

2. Higher machining efficiency—supporting high-speed cutting and shortening cycle times.

3. Better surface quality—meets the precision requirements of the brake disc friction surface.

4. Greater adaptability to operating conditions—high-temperature and impact resistance, suitable for interrupted cutting.