LBMP: CBN Grooving Inserts

One of the core applications of LBMP grooving Inserts is in the machining of cast iron brake discs. CBN grooving inserts were once the industry's leading choice in this area, but their limitations have gradually become apparent. To meet customer demands for improved machining efficiency, cost control, and adaptability, SCBN TOOLS continues to explore new tool materials and is committed to developing solutions that can replace traditional ceramic grooving inserts Currently, these new CBN groovinginserts have achieved technological breakthroughs in the machining of cast iron brake discs and have achieved successful results globally.

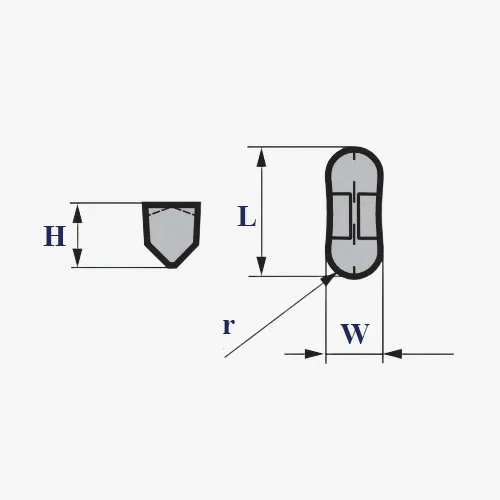

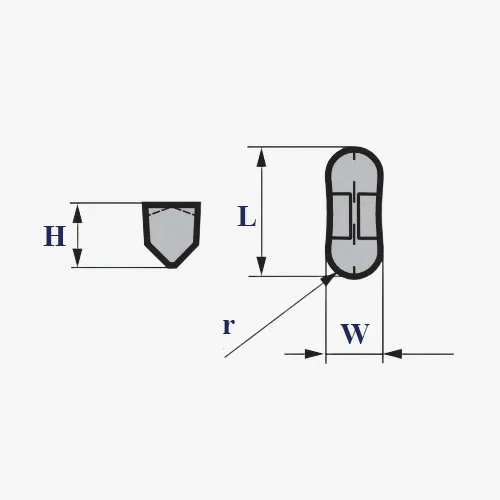

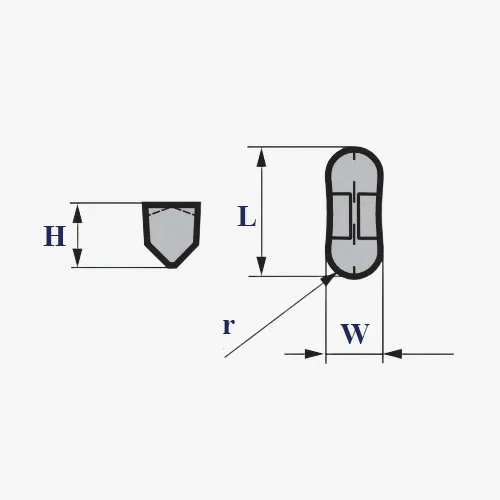

Common LBMP Grooving Inserts models are as follows:

| Model | L | W | H | r | Drawing |

| LBMP 15E 060 | 15 | 6 | 7.5

| 3

|

|

| LBMP 15E 070 | 15 | 7 | 7.5 | 3.5 |

| LBMP 15E 080 | 15 | 8 | 7.5 | 4 |

| LBMP 15E 100 | 15 | 10 | 7.5 | 5 |

| LBMP 12A 0400 | 12 | 4 | 5 | 2 |

| LBMP 12A 0500 | 12 | 5 | 5 | 2.5 |

| LBMP 12A 0600 | 12 | 6 | 5 | 3 |

| LBMP 12A 0700 | 12 | 7 | 5 | 3.5 |

| LBMP 12A 0800 | 12 | 8

| 5 | 4 |

All ceramic grooving inserts can be customized by SCBN to the corresponding CBN grooving inserts.

Ceramic Grooving Inserts

CBN Grooving Inserts(Brand: SCBN TOOLS)

When machining brake discs, CBN grooving inserts offer significant advantages over ceramic grooving inserts.

1. Longer tool life—reducing tool change time and costs.

2. Higher machining efficiency—supporting high-speed cutting and shortening cycle times.

3. Better surface quality—meets the precision requirements of the brake disc friction surface.

4. Greater adaptability to operating conditions—high-temperature and impact resistance, suitable for interrupted cutting.