Features and benefits of PCD End Mills

PCD end mill (Polycrystalline Diamond Tool, PCD for short) is a high-performance cutting tool, especially suitable for processing non-ferrous metals such as aluminum alloys and copper alloys as well as non-metallic materials.

The types of PCD end mills are flat PCD end mills, round nose PCD end mills, ball nose PCD end mills, PCD reamers and so on.

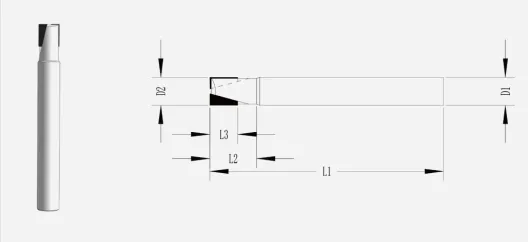

Flat PCD End Mill:It can perform fine or rough milling, milling grooves, removing large amounts of blanks, and fine milling of small horizontal surfaces or contours;

| Model | PCD Tips Diameter | PCD Tips Length/L3 | L2 | Shank Diameter/D1 | Total Length/L1 | Tips No.s F |

| Φ0.5*2H*2.5*Φ4*50L*1F*1F | 0.5 | 2 | 2.5 | 4 | 50 | 1 |

| Φ0.8*3H*3.5*Φ4*50L*1F | 0.8 | 3 | 3.5 | 4 | 50 | 1 |

| Φ1*3H*4*Φ4*50L*1F | 1 | 3 | 4 | 4/6 | 50 | 1 |

| Φ1.5*4H*5*Φ4*50L*1F | 1.5 | 4 | 5 | 4/6 | 50 | 1 |

| Φ2*6H*7*Φ4*50L*1F | 2 | 6 | 7 | 4/6 | 50 | 1 |

| Φ2.5*6H*7*Φ6*50L*1F | 2.5 | 6 | 7 | 4/6 | 50 | 1 |

| Φ3*6H*7*Φ6*50L*1F/2F | 3 | 6 | 7 | 4/6 | 50 | 1/2 |

| Φ4*6H*8*Φ4*50L*1F/2F | 4 | 6 | 8 | 4/6 | 50 | 1/2 |

| Φ5*6H*8*Φ6*50L*1F/2F | 5 | 6 | 8 | 5/6 | 50 | 1/2 |

| Φ6*6H*10*Φ6*50L*1F/2F | 6 | 6 | 10 | 6 | 50 | 1/2 |

| Φ8*6H*10*Φ8*75L*1F/2F | 8 | 6 | 10 | 8 | 75 | 1/2 |

| Φ10*6H*15*Φ10*75L*1F/2F | 10 | 6/8 | 15 | 10 | 75 | 1/2 |

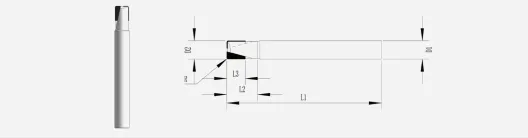

Round Nose PCD End Mill:It performs rough milling with small surface changes, fewer narrow concave areas, and more relatively flat areas.

| Model | PCD Tips Diameter/D2 | PCD Radius/R | PCD Length/L3 | L2 | Shank Diameter/D1 | Total Length/L1 | Tip No.s F |

| Φ1R0.2*3H*4*D4*50*1F | 1 | 0.2 | 3 | 4 | 4 | 50 | 1 |

| Φ2R0.3*6H*7*D4*50*1F | 2 | 0.3 | 6 | 7 | 4/6 | 50 | 1 |

| Φ3R0.3*6H*8*D4*50*1F/2F | 3 | 0.3 | 6 | 8 | 4/6 | 50 | 1/2 |

| Φ4R0.3*6H*8*D4*50*1F/2F | 4 | 0.3 | 6 | 8 | 4/6 | 50 | 1/2 |

| Φ6R0.5*6H*10*D6*50*1F/2F | 6 | 0.3 | 6 | 10 | 6 | 50 | 1/2 |

| Φ8R0.5*6H*10*D8*75*1F/2F | 8 | 0.5 | 6 | 10 | 8 | 75 | 1/2 |

| Φ10R0.5*6H*15*D10*75*1F/2F | 10 | 0.5 | 6 | 15 | 10 | 75 | 1/2 |

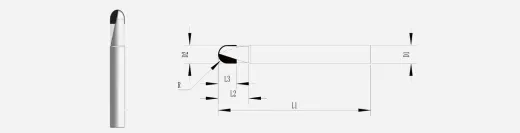

Ball Nose PCD End Mills:It performs semi-finishing and finishing milling of curved surfaces; the tool can finish mill small chamfers on steep surfaces/straight walls.

| Model | PCD Tips Diameter/D2 | PCD Radius/R | PCD Length/L3 | L2 | Shank Diameter/D1 | Total Length/L1 | Tips No.s F |

| R0.5*3H*4*D4*50*1F | 1 | 0.5 | 3 | 4 | 4 | 50 | 1 |

| R1*6H*7*D4*50*1F | 2 | 1 | 6 | 7 | 4 | 50 | 1 |

| R1.5*6H*7*D4*50*1F | 3 | 1.5 | 6 | 7 | 4/6 | 50 | 1 |

| R2*6H*8*D4*50*1F/2F | 4 | 2 | 6 | 8 | 4/6 | 50 | 1/2 |

| R3*6H*10*D6*50*1F/2F | 6 | 3 | 6 | 10 | 6 | 50 | 1/2

|

| R4*6H*10*D8*75*1F/2F | 8 | 4 | 6 | 10 | 8 | 75 | 1/2 |

| R5*8H*15*D10*75*1F/2F | 10 | 5 | 8 | 15 | 10 | 75 | 1/2 |

| R6*8H*4*D12*7*1F/2F | 12 | 6 | 8 | 15 | 12 | 75 | 1/2 |

PCD Reamers: It is suitable for non-ferrous metals, composite materials and other difficult-to-process materials with high hardness and high wear resistance.

| Model | PCD Tips Diameter/D2 | L2 | Total Length/L1 | Tips No.s F | Shank Diameter/D1 |

| D6*20*100*2F | 6 | 20 | 100 | 2 | 6 |

| D8*20*100*2F | 8 | 20 | 100 | 2 | 8 |

| D10*30*100*2F | 10 | 30 | 100 | 2 | 10 |

| D12*30*100*2F | 12 | 30 | 100 | 2 | 12 |

| D16*30*100*2F | 16 | 30 | 100 | 2 | 16 |

| D20*30*100*2F | 20 | 30 | 100 | 2 | 20 |

Application of PCD end mills:

Non-ferrous metals: copper, brass, gold, tungsten carbide, aluminum, aluminum alloy, aluminum casting alloy, magnesium aluminum alloy, silicon aluminum alloy

Non-metallic materials: composite materials, carbon fiber, glass fiber, grapsite, wood, stone, polyurethane, acrylic