What is the PCD milling inserts?

PCD Milling Inserts could meet different application of end millling and shoulder milling.Two cutting edges design and retip service which could help customers reduce their cost.Different types of cutting edge which can meet various application with different combinations.Realize both roughing and finishing in one tool.

APKT: The APKT insert is in the shape of a parallelogram, which allows the insert to better adapt to the machining surface when performing shoulder milling, achieving a more ideal cutting effect and ensuring that the machined shoulder is relatively flat. Its cutting edge back angle is 11 degrees, which helps to reduce friction between the tool and the workpiece, reduce cutting forces, improve cutting efficiency, and extend the service life of the insert.

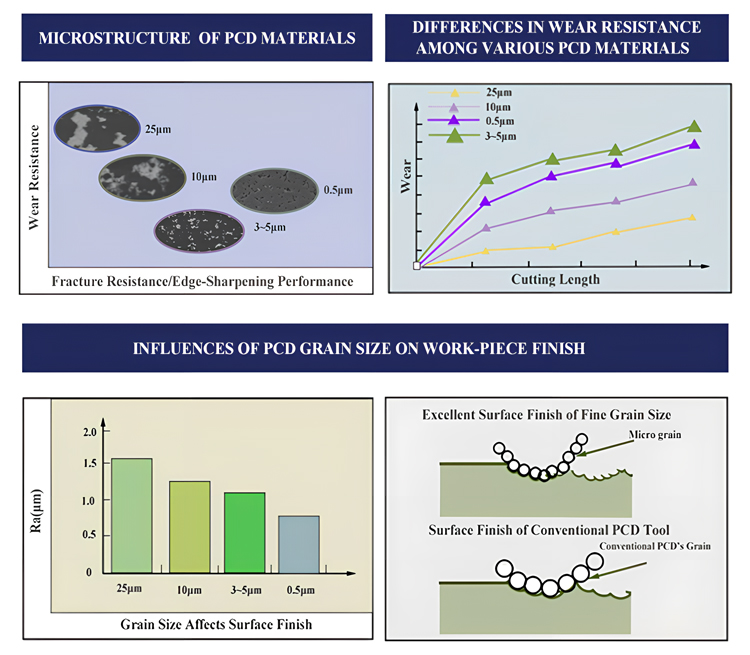

The following is a brief introduction to PCD materials:

Picture 1: 25µm represents the best wear resistance and the worst fracture resistance;

Picture 2: 25µm represents the worst wear and best cutting length;

Picture 3: Grain size affects surface finish;

Picture 4: Processing surfaces with different grain sizes.

Standard PCD milling inserts Models

Except above pcd milling inserts, we also can offer other inserts models as follows, only customers need offer drawings. At SCBN TOOLS, all types of customized inserts are available for you.