Views: Author: SCBN TOOLS Publish Time: 2025-11-06 Origin: Site

In the field of precision machining, CBN inserts, with their ultra-high hardness and high-temperature resistance, have become the core tool for machining high-hardness materials (such as hardened steel and wear-resistant cast iron). The choice between “coated” and “uncoated” inserts is not a simple superposition of performance, but a precise match based on machining requirements, material properties, and cost-effectiveness, which directly determines machining efficiency and tool life.

Advantages of Coated CBN Inserts:

1. Higher Hardness and Wear Resistance: The coating technology reduces tool wear.

2. Enhanced Impact Resistance: The coating reduces the risk of chipping during cutting.

3. Improved Cutting Performance: The coating reduces cutting forces and heat generation, thus improving machining accuracy and surface quality. It also facilitates higher cutting speeds and feed rates, increasing production efficiency.

4. Longer Tool Life: Due to the protective effect of the coating, the wear rate of the insert is slowed, extending its service life. This is particularly important for mass production and high-precision machining.

Here are some selection suggestions:

1. Consider machining requirements

If uncoated CBN inserts already meet machining requirements, such as machining accuracy, surface quality, and tool life, then there's no need to choose coated CBN inserts, as they are generally more expensive.

2. Consider machining parameters

For cutting speeds > 60 m/min and intermittent cutting, coated inserts are essential; for speeds < 40 m/min and precision cutting, uncoated inserts are more economical.

3. Consider cost-benefit balance

For small-batch precision parts machining, uncoated inserts offer better cost-effectiveness; for large-batch, continuous production, the longer lifespan of coated inserts reduces tool change frequency, thus reducing overall costs.

4. Consider tool usage

If uncoated CBN inserts experience rapid wear or chipping during use, consider replacing them with coated CBN inserts for better performance.

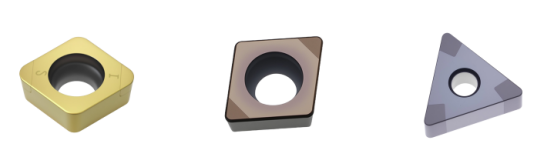

SCBN TOOLS currently offers three coating options: S1 (gold), S2 (copper), and S3 (purple). Each color represents different performance characteristics and is suitable for different working conditions. S1 offers excellent surface roughness and stability, S2 provides high wear resistance and stability, and S3 offers excellent heat resistance and collapse resistance. Choosing the appropriate coating type based on the material being machined and the cutting conditions can significantly improve tool life and machining efficiency. For example, S1 is suitable for finishing hardened steel, S2 is suitable for harsh conditions such as interrupted cutting, and S3 performs exceptionally well in machining high-temperature alloys.

Address : No. 11, Ruida Road, high tech Zone, Zhengzhou, Henan, CHINA

Tel : +86-13271567751

Fax : +86-0371-56705820

E-mail :scbntools@gmail.com

WeChat: scbntools annachina6