Views: Author: SCBN TOOLS Publish Time: 2025-11-06 Origin: Site

In the field of machining, cutting difficult-to-machine materials such as hardened steel, wear-resistant cast iron, and high-temperature alloys always faces pain points such as chip entanglement, rapid tool wear, and difficulty in controlling precision. Therefore, SCBN TOOLS launched CBN inserts with chip breaker. Through structural innovation, it overcomes the shortcomings of traditional cutting tools, achieving a perfect balance between “hard cutting” and “stable machining”, making it stand out in high-end manufacturing scenarios such as automotive part, mold manufacturing, and aerospace.

1. Precise Chip Breaking

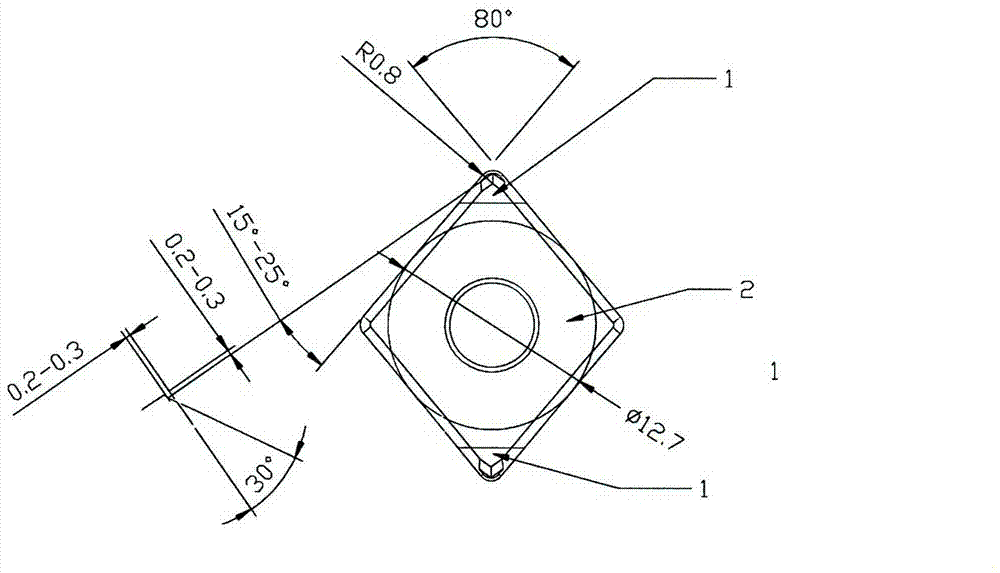

Cutting high-hardness materials easily produces ribbon-like or spiral chips that can entangle the cutting edge, scratch the workpiece, and even cause equipment failure. CBN inserts with chip breaker, through a precisely designed groove structure, form a closed-loop control of “guiding-compression-breaking” during the cutting process: after chip generation, the chip flows along the groove wall, and the curvature change and stress concentration effect of the groove force the chip to break at a preset position, forming short, uniform particles or curled chips, which are quickly discharged with the cutting fluid.

This design completely eliminates the industry pain point of chip entanglement and accumulation, reduces downtime for cleaning by more than 80%, ensures continuous mass production, and significantly improves productivity.

2. Stable Operating Conditions, Extended Tool Life

While CBN material is hard, its toughness is relatively weak. When machining with inserts without chip breaker, the secondary friction and compression of continuous chips can cause tool vibration, leading to edge chipping and accelerated wear. CBN inserts with chip breaker prevent chip accumulation through orderly chip breaking, reducing secondary friction and compression of chips on the tool, significantly reducing cutting vibration amplitude, and allowing for more even force distribution on the tool. Furthermore, the optimized design of the chip breaker can also optimize cutting force distribution and disperse the impact load on the cutting edge. In practical applications, its lifespan is increased by 40%-60% compared to non-chip breaker models, and the number of parts that can be machined with a single tool increases from hundreds to thousands, significantly reducing tool change frequency and production costs.

3. Improved Precision, Optimized Surface Quality

CBN inserts with chip breaker eliminate the risk of chip entanglement and scratches, directly ensuring the integrity of the machined surface and avoiding defects such as scratches and burrs. At the same time, stable cutting conditions reduce the interference of vibration on machining accuracy, allowing for more precise dimensional tolerance control. In addition, the chip breaker guides the direction of chip flow, which can prevent the chips from interfering with the heat conduction of the cutting zone, reduce the thermal deformation of the workpiece, and further ensure the stability of machining accuracy.

4. Wider Range of Applications

Traditional CBN inserts without chip breaker are only suitable for continuous cutting of simple rotating parts. However, the chip breaker design significantly broadens its application range: during high-speed cutting, it prevents chips from sticking to the workpiece and tool at high temperatures; in dry cutting conditions, the heat dissipation structure of the chip breaker reduces cutting temperature and minimizes tool thermal damage; when machining different materials such as ductile iron and high-temperature alloys, the chip breaking effect can be optimized through customized groove shapes, achieving “one tool for multiple materials and multiple working conditions.”

CBN inserts with chip breaker leverage material advantages through structural innovation, breaking through the efficiency and quality bottlenecks in machining high-hardness materials through four core highlights: “precise chip breaking, stable working conditions, upgraded precision, and full-scenario adaptability.”

Address : No. 11, Ruida Road, high tech Zone, Zhengzhou, Henan, CHINA

Tel : +86-13271567751

Fax : +86-0371-56705820

E-mail :scbntools@gmail.com

WeChat: scbntools annachina6