Views: Author: SCBN TOOLS Publish Time: 2025-11-04 Origin: Site

The core causes of CBN inserts wear:

1. Chemical wear: material reaction at high temperatures.

2. Mechanical wear: abrasive cutting and impact spalling of hard phases

3. Improper machining process: unreasonable parameters, insufficient cooling, etc.

4. Thermochemical wear: high temperatures lead to decreased hardness & accelerated chemical wear.

CBN inserts wear causes & solutions:

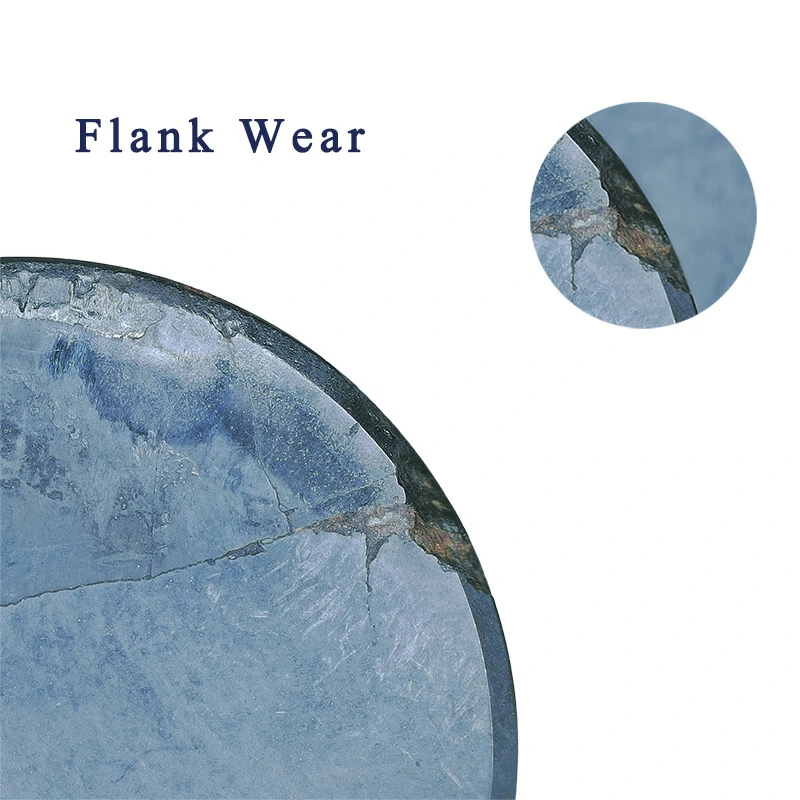

1. Flank Wear

Cause: Incorrect cutting speed

Solution: Reduce cutting speed, select a more wear-resistant grade, and use the correct cooling method.

2. Crater Wear

Cause: Incorrect cutting speed

Solution: Use coated inserts, use cutting fluid, reduce chip interference and heat, and reduce cutting speed and feed rate.

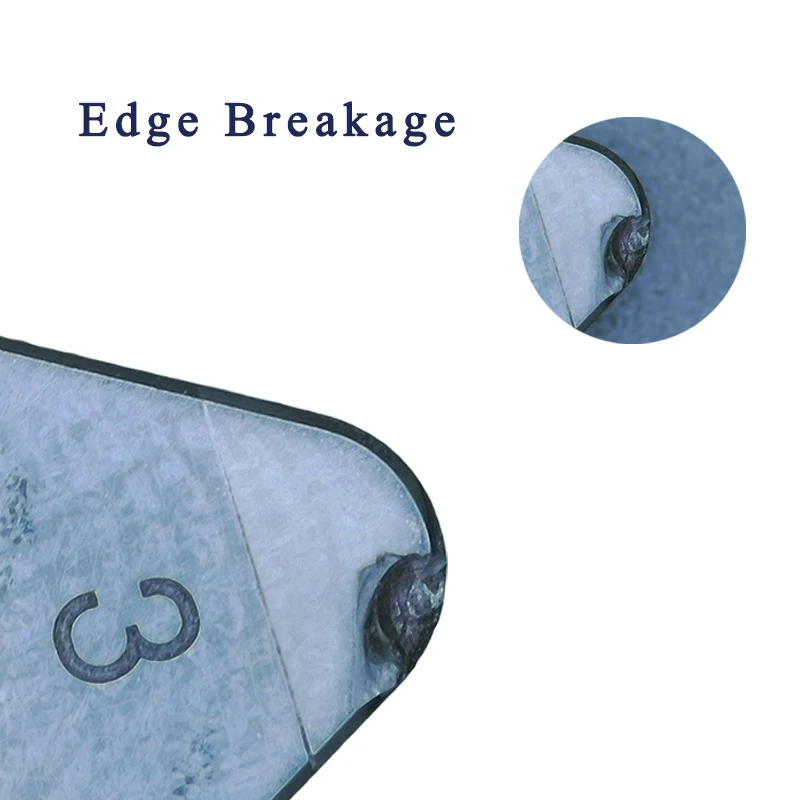

3. Edge Breakage

Cause: Incorrect tool use

Solution: Reduce feed rate and depth of cut, and use chip breaker inserts.

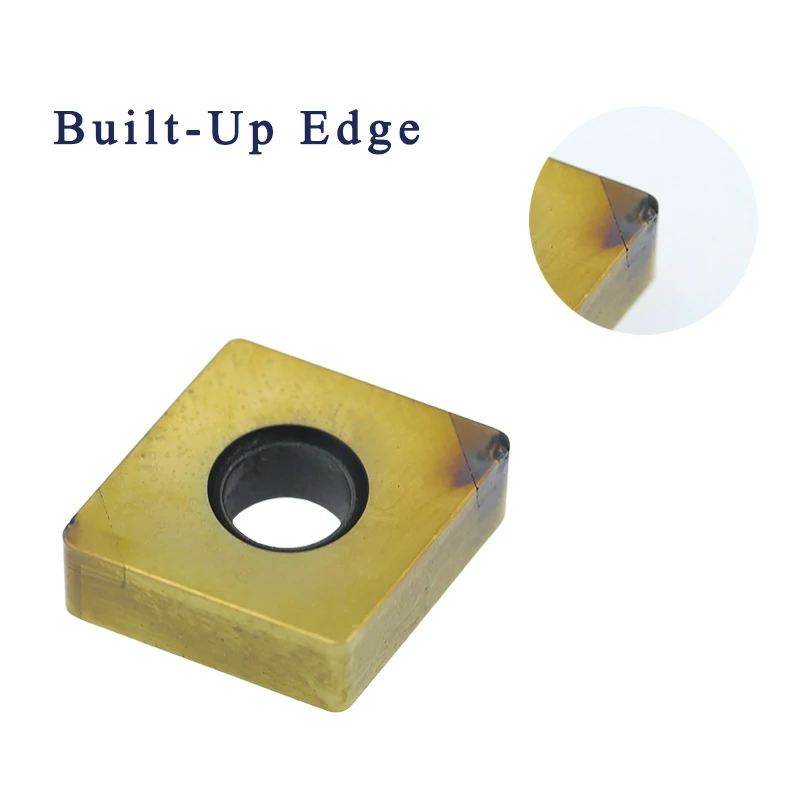

4. Built-up Edge

Cause: Formed when workpiece fragments are thermo-welded to the cutting edge.

Solution: Increase cutting speed and feed rate, select sharper insert flutes and smoother rake faces, use proper cutting fluid or increase cutting fluid concentration.

5. Groove Wear

Cause: Formed when the workpiece surface is harder or more abrasive than its underlying material

Solution: Reduce feed rate, use chip breaker inserts.

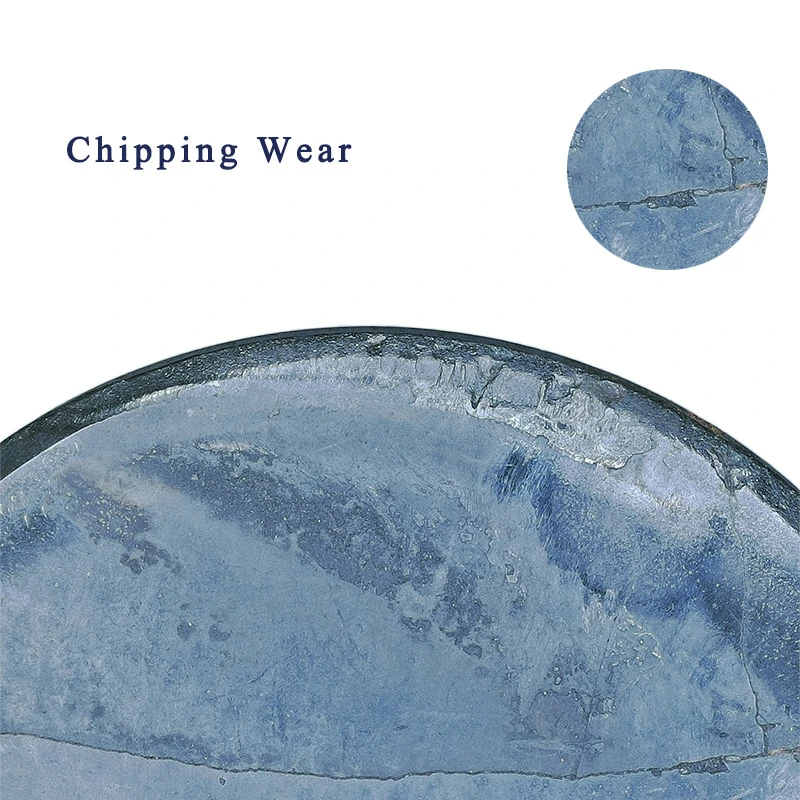

6. Chipping Wear

Cause: Caused by mechanical instability or cracks in the cutting material.

Solution: Ensure good machine tool accuracy, reduce feed rate, increase cutting speed.

Address : No. 11, Ruida Road, high tech Zone, Zhengzhou, Henan, CHINA

Tel : +86-13271567751

Fax : +86-0371-56705820

E-mail :scbntools@gmail.com

WeChat: scbntools annachina6