Views: Author: SCBN TOOLS Publish Time: 2025-11-03 Origin: Site

In the field of hard turning, tool performance directly determines machining efficiency, accuracy, and cost control. When facing difficult-to-machine materials such as hardened steel and chilled cast iron with hardness exceeding 55 HRC, SCBN TOOLS CBN tools, with their material innovation and process advantages, have become a highly efficient solution to replace traditional tools and grinding processes.

I. Core Performance Advantages

1. Ultra-hard and Wear-resistant, Doubled Lifespan

SCBN TOOLS CBN tools have a hardness second only to diamond. In machining bearing steel, hardened gears and other materials, their lifespan can reach 10-100 times that of carbide tools, significantly reducing downtime for tool changes.

2. Strong Adaptability to Extreme Conditions

The SBH series inserts possess excellent impact resistance and stability, covering all scenarios from continuous cutting to moderately interrupted to heavily interrupted machining. SBN series cutting tools can handle large-mast cuts, exhibiting stable performance in machining materials with a hardness of HRC45-68. They can even replace grinding processes, achieving “turning instead of grinding” , thus improving part fatigue strength and reliability.

3. Dual Breakthroughs in Precision and Efficiency

CBN material's thermal stability and low thermal conductivity above 1300℃ ensure no deformation of the cutting edge during high-speed cutting. Combined with precision manufacturing processes, it can stably control workpiece dimensional accuracy and surface roughness, achieving Ra0.4 or lower.

II. SCBN TOOLS Products Match Diverse Machining Needs

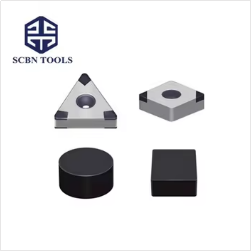

SCBN TOOLS has built a CBN cutting tool system covering different working conditions, balancing performance and economy:

1. SBH Series CBN Inserts: Outstanding cost-performance ratio, performance comparable to international brands, and more competitively priced, suitable for continuous and interrupted machining with small to medium machining allowances.

2. SBK Series CBN Inserts: Balanced wear resistance and impact resistance, suitable for semi-finishing and finishing with a cutting depth <2mm, making it an economical choice for cast iron machining inserts.

3. SBN Series CBN Inserts: Designed for difficult-to-machine materials, they perform exceptionally well in rough machining of bearings and precision machining of hardened steel, reducing machining steps and lowering unit costs.

III. Economic and Environmental Value

1. Lower Life Cycle Costs

Although the initial purchase cost of CBN tools is higher than that of carbide tools, their extended lifespan and high-efficiency machining lead to a reduction in overall costs. Taking automotive brake disc machining as an example, the SBN series inserts, leveraging the advantages of a fully self-sufficient supply chain, achieve a lower price point while maintaining performance equivalent to imported brands, reducing unit machining costs by more than 30%.

2. A Natural Fit for Green Manufacturing

SCBN TOOLS inserts support dry cutting, enabling stable machining without coolant, reducing environmental pollution and wastewater treatment costs. Their long lifespan reduces the amount of discarded tools, and combined with the energy savings from efficient cutting, they perfectly meet the green production needs of modern manufacturing.

IV. Reliable Technical Support

As an integrated industrial and trading company, SCBN TOOLS has achieved independent control over the entire super hard materials industry chain, passed ISO9001 quality system certification, and is at the forefront of material research and application technology in China. Its products are widely used in the automotive, aerospace, and bearing industries, and are exported to industrial power such as Germany and Italy, providing customized cutting solutions for global customers.

In the trend of hard turning technology transforming towards high efficiency, precision, and green practices, SCBN TOOLS CBN tools, with their core advantages of “high performance, wide adaptability, and cost-effectiveness”, redefine the efficiency boundaries of hard machining, becoming a key tool for cost reduction and efficiency improvement in the manufacturing industry.

Address : No. 11, Ruida Road, high tech Zone, Zhengzhou, Henan, CHINA

Tel : +86-13271567751

Fax : +86-0371-56705820

E-mail :scbntools@gmail.com

WeChat: scbntools annachina6