Solid CBN inserts, short for solid polycrystalline cubic boron nitride inserts, are made from cubic boron nitride powder that is polymerized under high temperature and pressure. They are machine-clamped inserts and require custom toolholders, unlike those used with conventional carbide and PCBN inserts.

Through-welded PCBN inserts are cutting tools used in machining processes requiring high precision and durability. PCBN stands for polycrystalline cubic boron nitride, a superhard material with cutting performance second only to diamond.

Currently, in mass production, there is a growing demand for high-speed machining of cast iron parts, but traditional machining tools have obvious limitations. These challenges directly drive the demand for tools with higher durability and reliability. The "SBN850" grade was born in this context.

Product Features of SCBN SBN850

1. Solid CBN material suitable for high-speed, efficient machining;

2. All-CBN construction suitable for deep-cutting applications;

3. Cost-effective multi-edge design.

SCBN TOOLS recommends the cost-effective grade SBN850 for machining cast iron

TNGA1604-6N, WNGA0804-6N, VNGA1604-4N

CNGA1204-4N, DNGA1504-4N, DNGA1506-4N

DNGN1104, DNGN1504, TNGN1103, TNGN1604

SNGN0904, SNGN1204, SNGN1207, SNGN1507

CNGN0904, CNGN1204, CNGN1207, CNGN1507

RNGN0604, RNGN0903, RNGN1204, RNGN1507

WNGN0804, SCGN0904, RCGX2012, RCGV2512

Tool features of SCBN TOOLS:

1. Provide customized PCBN inserts to best meet customer needs.

2. Utilize the latest coatings and grades to solve customer problems.

3. Processing performance and service life are comparable to those of top international brands, while reducing costs and improving the market competitiveness of our customers' products.

SCBN TOOLS can offer all kinds of inserts and customized service.

If you are a brake disc and brake drum customer, please click the link below:

The following are typical cast iron cases:

Case 1

| Workpiece Name: Flange |  |

Workpiece Material | gray cast iron

|

| Workpiece Hardness | HB220 |

| Processing Location | out circel, end face |

| Processing Type | continuous, finishing |

| Grade & Model | SBN850 WNGA080408 |

| Cutting Parameters | Vc(m/min): 534 ap(mm): 0.4 Fr(mm/r): 0.26 |

| Efficiency (seconds/piece) | 25 |

| Lifespan (pieces/edge) | 300 |

Case 2

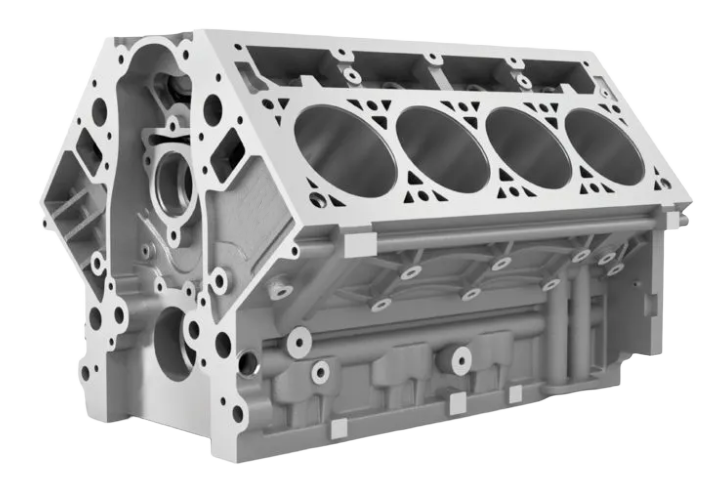

| Workpiece Name: Engine Block |

|

Workpiece Material | cast iron

|

| Workpiece Hardness | HB190~210 |

| Processing Location | cylinder top surface |

| Processing Type | Intermittent, finishing |

| Grade & Model | SBN850 SNEN090412 |

| Cutting Parameters | Vc(m/min): 470 ap(mm): 0.5 Fr(mm/min): 2000 |

| Efficiency (seconds/piece) | 15 |

| Lifespan (pieces/edge) | 400 |

Case 3

| Workpiece Name: Flywheel |

|

Workpiece Material | cast iron

|

| Workpiece Hardness | HB190 |

| Processing Location | plane and inner diameter |

| Processing Type | finishing |

| Grade & Model | SBN850 RCGV090700 |

| Cutting Parameters | Vc(m/min): 247 ap(mm): 0.5 Fr(mm/r): 0.2 |

| Efficiency (seconds/piece) | 18 |

| Lifespan (pieces/edge) | 100 |

Case 4

| Workpiece Name: slurry pump-impeller |  |

Workpiece Material | wear-resistant white cast iron |

| Workpiece Hardness | HRC50 |

| Processing Location | chamfer |

| Processing Type | heavy interrupt, roughing |

| Grade & Model | SBN950 SNGN120712 |

| Cutting Parameters | Vc(m/min): 55 ap(mm): 2~3mm Fr(mm/r): 0.3 |

| Efficiency (seconds/piece) | 10 |

| Lifespan (pieces/edge) | 2 |