The gray cast iron grades used in automobile brake discs mainly include: G3000, FC350, GG40,FG400.

The main reason for using gray cast iron in brake discs is its excellent heat and wear resistance, which allows it to withstand the demanding high-frequency friction conditions of brake systems.

A review of international brake disc machining technology reveals significant limitations in traditional solutions:

① Carbide + ceramic inserts: These methods suffer from low cutting efficiency, poor surface finish, high friction, high casting stress etc.

② PCBN welded inserts: Roughing and finishing machining require two separate machine tools.

New Solution for brake disc:

In response to the limitations of ceramic inserts in brake disc machining, SCBN continues to research and develop breakthroughs, launching new brake disc solutions, using its technological strength to efficiently solve problems for customers. Solid PCBN inserts(SBN850): These enable "roughing and finishing" machining—roughing, semi-finishing, and finishing can be performed continuously in a single setup, significantly improving production efficiency.

SCBN TOOLS, SBN850 grade CBN inserts are an ideal choice for brake disc machining. With its long life, high precision, and cost-effectiveness, this grade perfectly matches the efficient machining needs of gray cast iron brake discs, providing manufacturers with a solution that combines performance and cost advantages.

Ceramic Inserts

CBN Inserts(grade: SBN850 Brand: SCBN TOOLS)

All ceramic inserts can be customized into corresponding CNB inserts(SBN850) according to the drawings

SCBN TOOLS, the inserts have many advantages such as high hardness, high wear resistance, thermal stability, impact resistance, etc., and have significant advantages in the field of machining.

SBN850 is a CBN grade composed of a CBN grain size optimized for cast iron machining and a specialized binder, offering excellent wear resistance and high heat resistance. Its core features include:

1. Solid CBN grade suitable for high-speed, high-efficiency machining;

2. All-CBN construction suitable for deep-cutting applications;

3. Cost-effective multi-edge design.

CBN Inserts for brake disc:

CNGN120404, CNGN120408, CNGN120412, CNGN120416

CNGN120704, CNGN120708, CNGN120712, CNGN120716

SCGN090404, SCGN090408, SCGGN090412, SCGN0904W

SNGN120404, SNGN120408, SNGN120412SNGN120712, SNGN120716

VNGX160712, VNGX160716, VNGX160735

CNGX120408, CNGX120412, CNGX120416, CNGX120712, CNGX120716

DNGX120412,DNGX120716, DNGX120712, DNGX150712, DNGX1500716

SNGX120408, SNGX120412, SNGX120416, SNGX120708, SNGX120712, SNGX120716

Advantages of CBN inserts(SBN850) over ceramics:

1. Ceramics are often used for finishing conditions, while CBN can be used for both roughing and finishing, without changing insert during processing, which greatly improves efficiency;

2. CBN have better wear resistance, and have longer tool life of 5-7 times that of ceramics, but the price is not 5-7 times that of ceramics, CPC is low;

3. CBN can directly replace the same type of ceramics with various Dimple which needed in brake disc processing, like CNGX, DNGX, VNGX, TNGX,SNGX and so on.

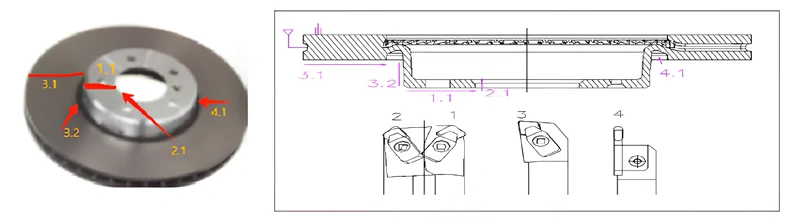

Current advanced brake disc processing scheme

| Processing No. | Processing Part | CBN Models | Vc(m/min) | Fr(mm/r) | ap(mm) |

| 1.1 | wheel face Roughing | CNGN120412 | 400-500 | 0.3~0.5 | 1.5~2 |

| 2.1 | internal roughing | CNGN120412 | 400~500 | 0.3~0.5 | 1.5~2 |

| 3.1 | pad face roughing | CNGN120412 | 400-500 | 0.3~0.5 | 1.5~2 |

| 3.2 | wheel external roughing | CNGN120412 | 400~750 | 0.3~0.5 | 1.5~2 |

| 4.1 | groove roughing | RCGX060500 | 550~700 | 0.1~0.3 | 0.2~0.5 |

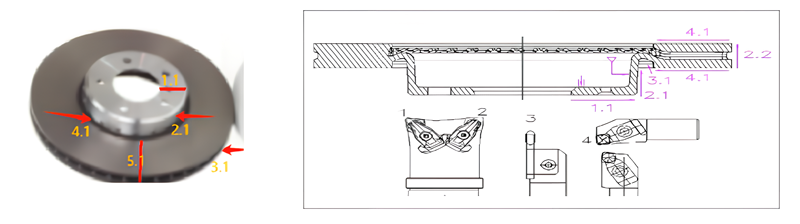

Second Process

Processing No.

| Processing Part | CBN Models | Vc(m/min) | Fr(mm/r) | ap(mm) |

| 1.1 | external roughing | CNGN120412 | 400~750 | 0.3~0.5 | 1.5~2 |

| 2.1 | pad face roughing | CNGN120412 | 400-500 | 0.3~0.5 | 1.5~2 |

| 3.1 | starting point roughing | CNGN120412 | 400-500 | 0.3~0.5 | 1.5~2 |

| 4.1 | internal roughing | CNGN120412 | 400~750 | 0.3~0.5 | 1.5~2 |

| 5.1 | internal finishing | CNGN120412 | 550~750 | 0.1~0.3 | 1.5~2 |

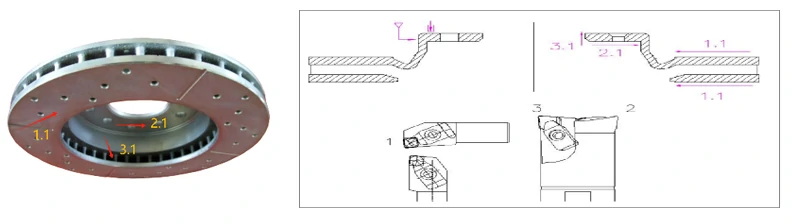

Third Process

| Processing No. | Processing Part | CBN Models | Vc(m/min) | Fr(mm/r) | ap(mm) |

| 1.1 | wheel face finishing | CNGN120412 | 650~750 | 0.2~0.3 | 0.2~0.5 |

| 2.1 | wheel external finishig | CNGN120412 | 650~750 | 0.2~0.3 | 0.2~0.5 |

| 3.1 | external finishing | CNGN120412 | 650~750 | 0.2~0.3 | 0.2~0.5 |

| 4.1 | Groove finishing | RCGX060500 | 550-700 | 0.1~0.2 | 0.2~0.5 |

| 5.1 | pad face semi-finishing | SCGN090408W | 650~750 | 0.2~0.3 | 0.2~0.5 |

Forth Process

Processing No.

| Processing Part | CBN Models | Vc(m/min) | Fr(mm/r) | ap(mm) |

| 1.1 | pad face finishing | SCGN090408W | 650~750 | 0.2~0.3 | 0.2~0.5 |

| 2.1 | starting point finishing | CNGN120412 | 650~750 | 0.2~0.3 | 0.2~0.5 |

| 3.1 | internal finishing | CNGN120412 | 650~750 | 0.2~0.3 | 0.2~0.5 |

Machining Precision Advantages

1. Dimensional Stability: The machining solution reduces cutting forces and internal stress in the brake disc, minimizing dimensional fluctuations after finishing.

2. Braking Surface Accuracy: The SBN850 solid CBN inserts offer long life and excellent indexing, ensuring dimensional stability and parallelism of the braking surface, improving driving stability and braking performance.

Summary

1. Industry Status: Most domestic and international brake disc manufacturers have achieved fully automated production. CBN inserts are a mature technology in machining brake disc, having replaced alloy-coated and ceramic inserts as the mainstream.

2. Customization: For users who prefer to avoid toolholder changes and use a variety of ceramic inserts, we offer customized positioning pits.