Views: Author: SCBN TOOLS Publish Time: 2025-12-24 Origin: Site

The emergence of CBN wiper inserts, with their innovative geometric design, has broken through the limitations of traditional cutting theory, achieving a synergistic improvement in both processing efficiency and surface quality, and becoming one of the core competitive advantages in the field of CNC machining.

I. Core Differences Between CBN Wiper Inserts and Traditional Inserts

1. Geometric Structure Differences

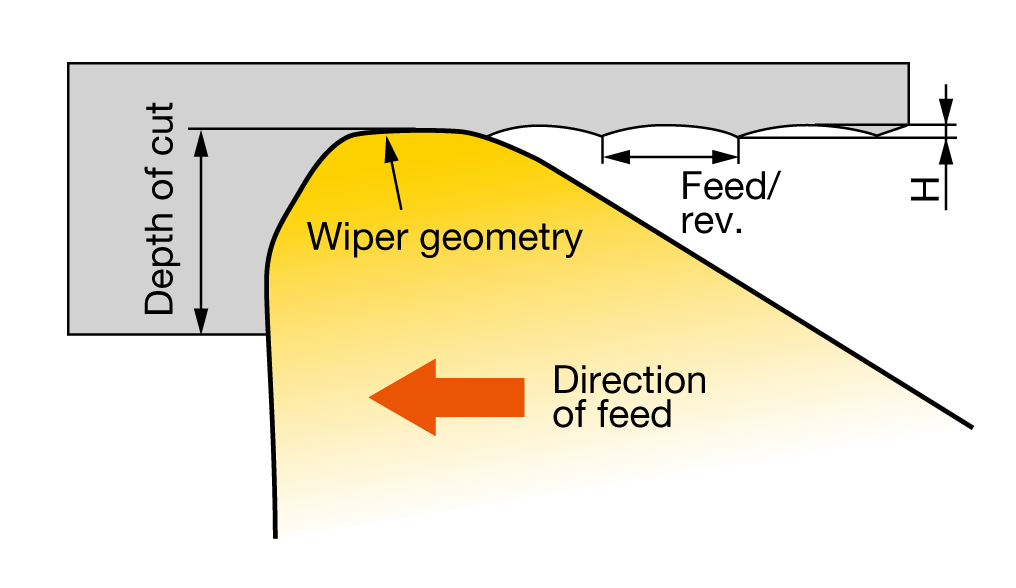

Traditional inserts have a single circular arc cutting edge with a simple transition between the cutting edge and the tip;CBN wiper inserts utilize a composite curve design, resulting in a smooth transition between the tip and the secondary cutting edge. The finishing edge segment is strictly parallel to the feed direction (straightness of 0.1~0.2μm), ensuring a superior finishing effect.

2. Cutting Performance Differences

The surface roughness of traditional inserts is greatly affected by the feed rate; increasing the feed rate leads to a decrease in surface quality. CBN wiper inserts can reduce roughness by more than half at the same feed rate, or allow for a more than twofold increase in feed rate while maintaining the same surface quality.

3. Application Effect Differences

Traditional inserts require both rough and finish machining processes; CBN wiper inserts can combine these processes, directly achieving a surface roughness of Ra0.8μm or less at high feed rates, shortening the processing cycle, and simultaneously reducing wear and tear, thus extending tool life.

II. Core Advantages and Classification of CBN wiper inserts

Core Technological Advantages

1. Superior surface quality: Secondary cutting removes minute tool marks, consistently achieving a surface finish of Ra0.8μm or less, meeting the demands of high-end applications.

2. High processing efficiency: Feed rates can be more than twice that of traditional inserts, allowing for the combination of rough and finish machining processes, shortening processing time.

3. Long tool life: Dispersed cutting forces reduce tool tip wear, extending service life.

4. Excellent chip control: Increased chip thickness and easy chip breakage and removal reduce chip accumulation and scratching.

Main Types and Applicable Scenarios

Based on geometric shape, CBN wiper inserts are mainly divided into two types, each with its own focus:

1. Arc-shaped CBN wiper inserts: Large radius arc design provides uniform finishing and reduces waviness, suitable for high-gloss applications such as precision shafts and mold cavities; requires a high-rigidity machine tool due to larger cutting forces.

2. Straight-line CBN wiper inserts: Flat structure with a secondary rake angle close to 0°, reducing vibration, suitable for scenarios where arc-shaped transition edges are difficult to grind, for machining symmetrical parts, and for machine tools with average rigidity, such as face milling and end turning.

III. Typical Application Fields of CBN wiper inserts

1. Automotive Manufacturing

Suitable for machining critical parts such as crankshafts, camshafts, and hydraulic cylinder bores, it can increase feed rate by more than 100%, control surface roughness to Ra0.4~0.8μm, ensure part interchangeability, and improve production line efficiency.

2. General Machinery Manufacturing

Suitable for turning and milling of shaft, sleeve, and disc-shaped parts, compatible with both ordinary steel and high-strength steel. For example, in gear end face machining, it can remove tool marks and improve meshing accuracy.

Address : No. 11, Ruida Road, high tech Zone, Zhengzhou, Henan, CHINA

Tel : +86-13271567751

Fax : +86-0371-56705820

E-mail :scbntools@gmail.com

WeChat: scbntools annachina6