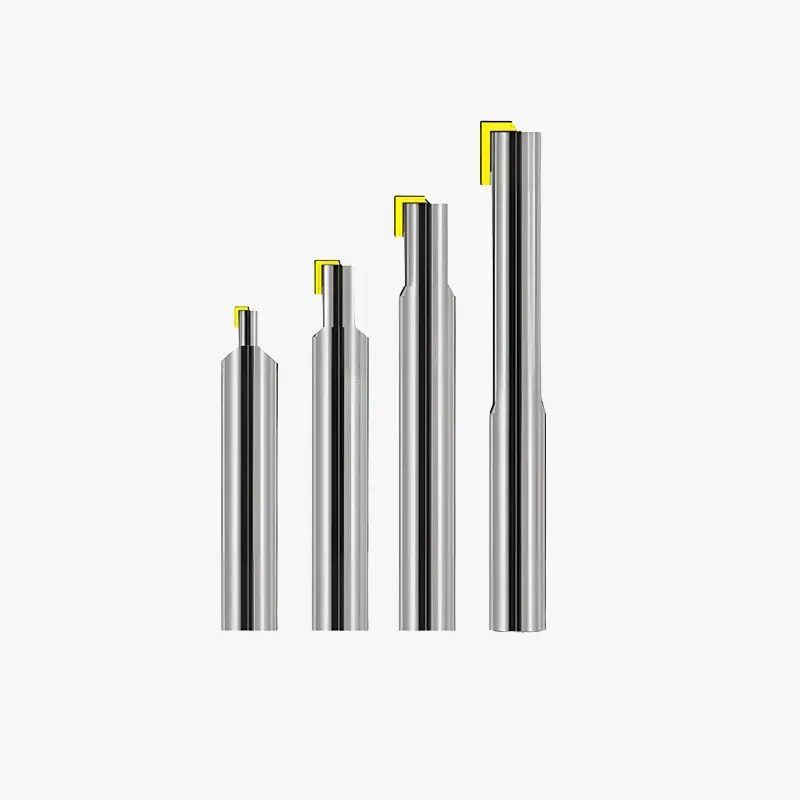

Monocrystalline End Mills(MCD End Mills)

MCD CuttingTools is a synthetically produced diamond material with a hardness very close to that of natural diamond. Due to its very high hardness, it is particularly suitable for machining abrasive materials.

Therefore, Cutting Tools with MCD cutting material are very suitable for machining lightweight materials such as aluminum, magnesium alloys and fiber-reinforced plastics. When using MCD Tools for peripheral milling, fewer radius corrections are required before the end of tool life compared to solid carbide tools, which significantly increases process security.

Single crystal cutting tools are widely used in many fields, mainly including the following aspects:

Mechanical processing field: MCD End Mills play an important role in the field of mechanical processing and are widely used in the processing of ultra-precision mirror parts. Their high hardness, wear resistance, thermal conductivity and chemical stability make them ideal materials for ultra-precision cutting. Such as

1. Semiconductor manufacturing industry: MCD End Mills are one of the indispensable tools in semiconductor processing, mainly used for cutting and grinding silicon wafers and other materials.

2. Solar photovoltaic industry: In the preparation process of solar cells, MCD End Mills are needed for slicing. In addition, MCD End Mills are also used to make other components in solar power stations such as brackets.

3. Other fields: MCD End Mills are also used in the processing of civilian products such as watch parts, aluminum pistons, jewelry, as well as the processing of pens, high-gloss signs and non-ferrous metal mirror decorative parts.

At SCBN TOOLS, all types of customized inserts are available for you.