Grey Cast Iron Machining Solutions

Gray cast iron is still widely used in brake discs, brake drums, flywheels and other auto parts, as well as motor casings (frames) in the motor industry due to its good shock absorption and wear reduction, low processing cost and simple production process. motor end caps; air-conditioning compressor parts; and in the machining of automotive gearboxes, cylinder blocks, and machine tool guide rails.

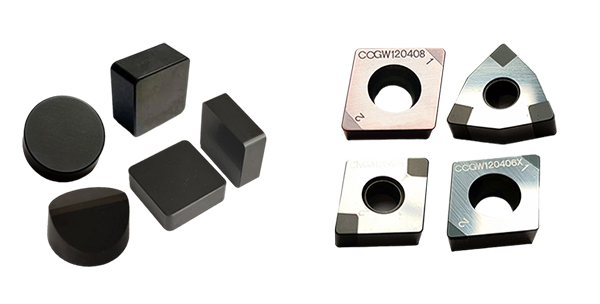

SCBN TOOLS CBN INSERTS

1. CBN INSERT is an ideal tool for mass production of gray iron castings, which can withstand high temperature, high speed, intermittent and other working conditions, especially for SBN800 material, the maximum linear speed reaches 2000m/ Min, on the basis of not considering the rigidity of the machine tool, and encountering hard points at the same time, the white mouth structure does not need to be annealed first, and the workpiece can be directly processed without chipping.

2. The cylinder block and cylinder hole of automobile engine are typical gray cast iron parts. At present, the CBN INSERT of most production enterprises performs finishing and semi-finishing processing of the cylinder block and cylinder hole.

3. The CBN INSERT of the SBN800 grade has a large particle size and a high content of cubic boron nitride, which can achieve stable cutting under high temperature conditions. It is mainly used in the processing of aerospace iron parts and gray iron parts in the automotive industry. Large stock and interrupted cuts in grey cast iron.

For machining gray cast iron, SCBN TOOLS: SBN850, SBN900 tools can be used to process, which has the following advantages:

(1) High hardness;

(2) Good wear resistance and impact resistance;

(3) High-speed machining of brake discs;

(4) The finish can reach above Ra1.6;

(5) Dry cutting and turning of gray cast iron tools to reduce environmental pollution

(6) Multiple cutting edges (eight cutting edges), it is more economical to process gray cast iron

(7) The line speed reaches 350m/min, and the high-speed machining of gray cast iron parts has high efficiency and can ensure the surface quality and smoothness requirements of gray cast iron, and the smoothness reaches Ra0.8.

(8) The cutting speed can be adjusted between 200-700m/min. The high-speed machining of gray cast iron and the eight cutting edges of the square blade are more economical.

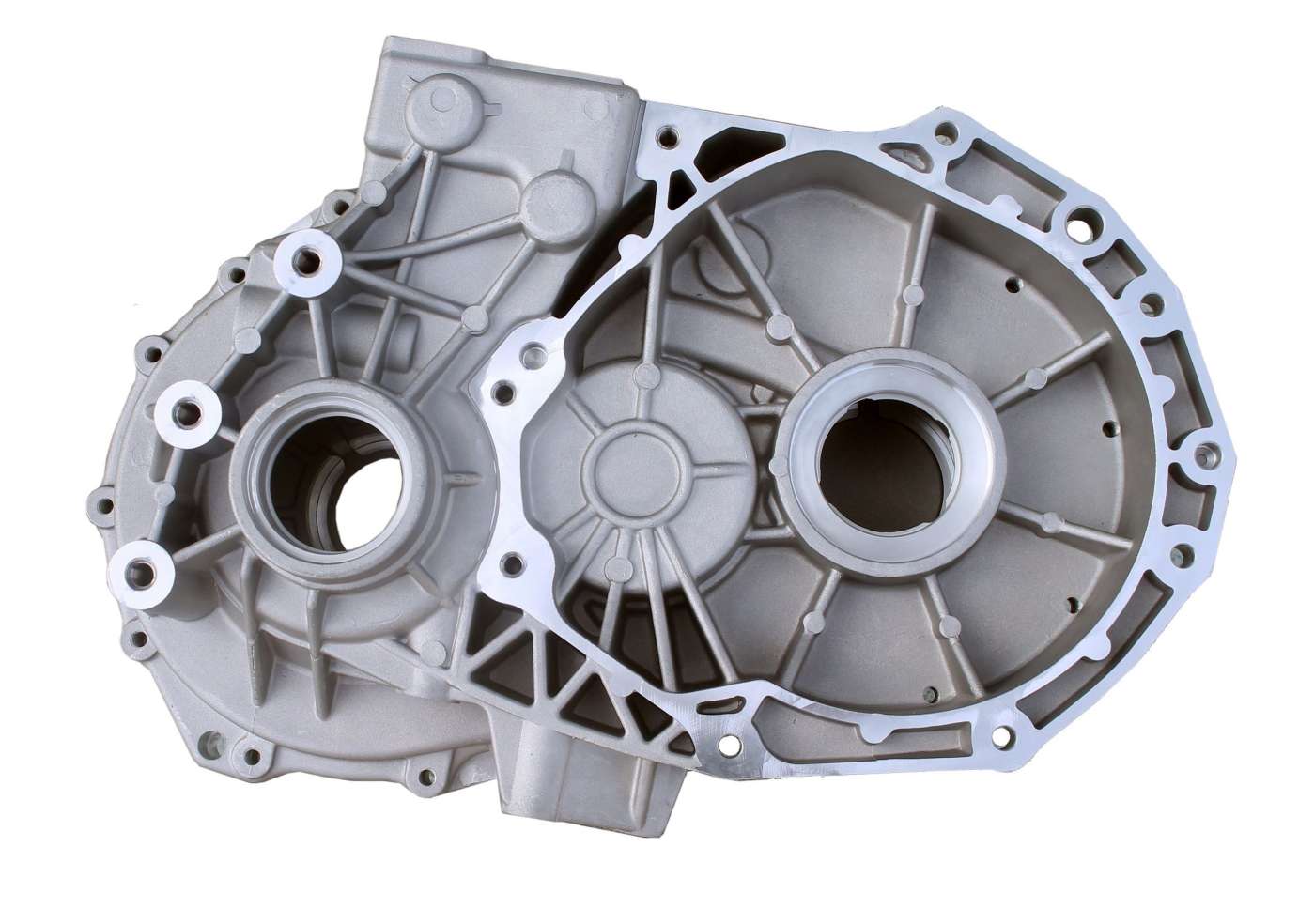

Processing scheme of automobile gearbox case

Processing part: box face milling

Workpiece material: gray cast iron

Hardness: HB200-300

Machining process: semi-finishing, fine-milling

Blade: SNFN120412 CBN insert

Processing parameters:

cutting depth: ap=2mm Feed speed: f=5000mm/min Speed: n=6000r/min

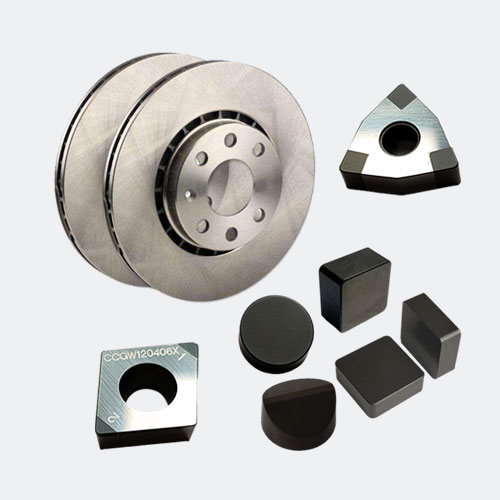

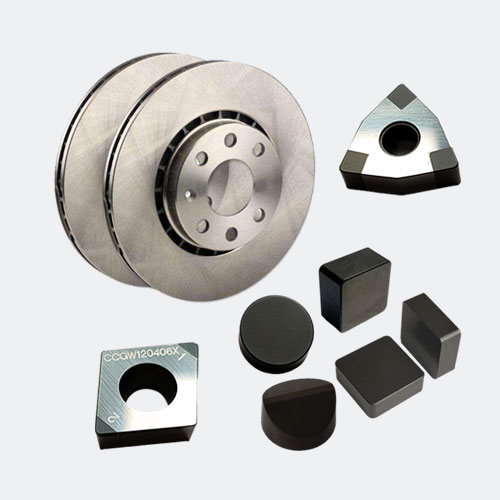

Gray cast iron brake disc machining

1. SOLID CBN insert SBN850 CNMN

2. BRAZED PCBN INSERTS SBN850 CNGA

3. BRAZED PCBN INSERTS SBN850 WNGA

Processing parts: brake disc outer circle, end face, inner hole

Machining process: Rough turning and finishing turning

Advantages: The material is specially developed for cast iron machining, with excellent impact resistance and high wear resistance, ensuring the machining accuracy of the workpiece, prolonging the tool life and improving the machining efficiency.

Gray cast iron brake drum machining

1. SOLID CBN insert SBN850 CNMN

2. BRAZED PCBN INSERTS SBN850 CNGA

3. SOLID PCBN blade SBN850 WNGA

Processing part: outer circle of brake drum, inner hole

Machining process: Rough turning and finishing turning

Advantages: One clamping, all rough and finishing machining is completed, and better surface quality can be obtained